Examination prior to welding: Material receiving and traceability inspection. Examine the dimension and location according to drawings. Check fit-up of joints according to requirement of specifications, WPS, code or procedure.

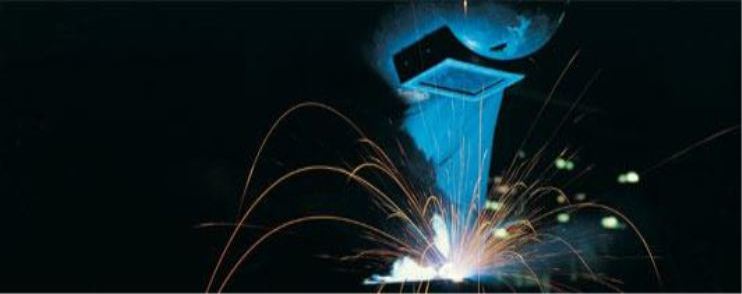

In-process control during welding. Check if the welder’s qualification meets requirements of the work. Confirm if parameter in welding meet requirements of WPS (preheat temperature, inter-pass temperature, width of weave, current, voltage, travel speed, heat input). Check if welding repair, welding material protection and control of welding distortion is in accordance with procedural requirements.

Visual inspection after welding. Check whether there is excess discontinuity existing in the completed weld. Check whether the overall completed structure meets the specifications.